Reactive Dyes

Price 70 INR/ Kilograms

Reactive Dyes Specification

- Water Resistance

- Excellent

- Solvent Color

- Bright, depending on specific dye shade

- Other Names

- Reactive Color, Fiber Reactive Dye

- Shelf Life

- 24 Months (when properly stored)

- Smell

- Odorless

- Molecular Formula

- Varies depending on color (typically contains chromophores with azo or anthraquinone groups and reactive sites)

- Size

- Customized as per client requirement

- Structural Formula

- Varies (Contains Reactive Groups e.g. Haloheterocyclic, Vinyl Sulfone)

- Solubility

- Soluble in water

- Resistance

- Good Light & Wash Fastness

- Moisture (%)

- <1%

- Rubbing Resistance

- Very Good

- HS Code

- 32041600

- Purity

- 99% Min

- Melting Point

- Decomposes before melting (typically >180C)

- Grade

- Industrial Grade

- Application

- Cellulose Fibers (Cotton, Viscose), Wool, Nylon

- Taste

- Odorless

- Shape

- Fine Powder / Granules

- Type

- Reactive Dyes

- Usage

- Textile Dyeing and Printing

- Physical Form

- Powder / Granular / Liquid

- Packaging

- 25 kg HDPE Bags with Inner Liner, Jumbo Bags also available

- Compatibility

- Suitable for exhaust, pad, and printing dyeing methods

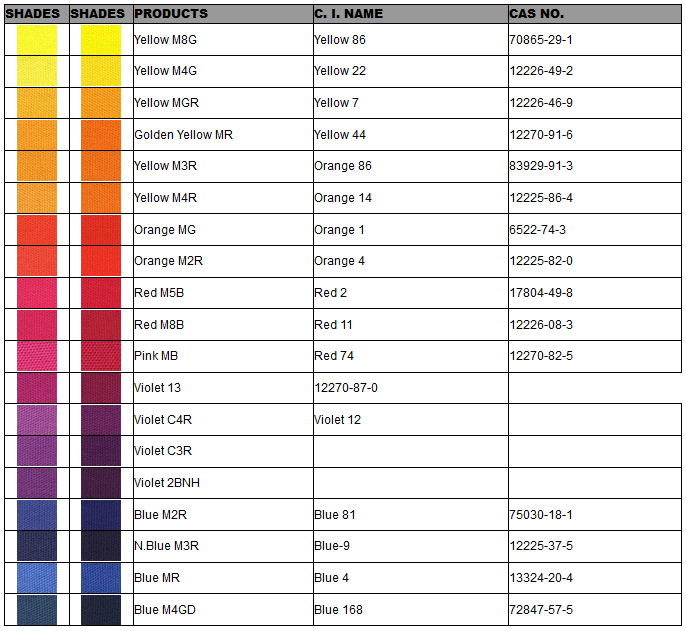

- Color Range

- Available in a wide range of shades, including Yellow, Red, Blue, Orange, Black, Green, Violet

- Safety Precautions

- Use gloves and mask; avoid inhalation of dust during handling

- Storage Conditions

- Store in a cool, dry place away from moisture and direct sunlight

Reactive Dyes Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

About Reactive Dyes

Reactive Dyes : Reactive Dyes What Are They?

Reactive Dyes : Application Of Reactive Dyes

Reactive dyes are ideal for cottons or other plant material as they are highly wash fast and colorfast. These are the absolute best dyes type developed for fibres or fabrics made from plant material. Fibre reactive dyes act best with cellulose (plant) fibres such as cotton, rayon and linen. Suitable for tinting textiles, they work well on silk also.

Products Features:

- Impurities Free Products, Without Side Effects, Heat Stability Is Good & Moisture Free Dyes

- Composition Is Accurate, It Is Very Safe To Use, It Very Easy To Use & Non-Toxic Dyes

- Minimal Side Effects, Highly Concentrated Dyes, Fastness Properties Is Excellent & Excellent Solubility Properties

- Excellent Quality, Non-Caustic Dyes Products, Tinting Strength Is High & Good Fastness Properties

Why We : Product Reviews & Comparisons With Others Dealers & Manufacturer

- We Use Latest Production Methods & Machines for Making all type of Dyes which Make us Unique from others.

- We offered Cost-Effective & Trustable Products, that is are our Aim

- Qualitative Results: Our Expert team Check the Quality of product.

- Reactive Dyes is used in Wide Area like Textile Industries, Fiber Industries, etc

- Autoclaves and reaction vessels is Distillation in High vacuum for set up all type of Dyes.

- We Use Wide Collection of Production Utilities to Make Excellent Dyes like hot oil unit, chilling plants, generators, boiler, etc.

- We have Our Self Quality Control Lab for Analysis of Our Products

- We Use Packing & Drying areas Separated for Both Purpose.

- Our Products & its raw materials are Stock in Highly spacious warehouses

- Quality Control Wing

- Expert Team

- Excellent Distribution Network

Versatile Color Options for Every Textile Need

Our reactive dyes come in an extensive range of shades, from subtle yellows to deep blacks and greens, enabling precise color matching for any design or application. The vibrant and bright solvent colors can be tailored to client requirements, assuring high-quality color consistency for every batch.

Safety and Storage for Optimal Performance

Always store reactive dyes in a cool, dry area, away from sunlight and moisture, to maintain their potency and shelf life. Adhering to recommended safety measures, such as wearing gloves and masks while handling, helps prevent accidental inhalation and ensures a safer workspace for operators.

Application Adaptability and Dyeing Methods

These dyes are compatible with various application processesincluding exhaust, pad, and printing methodsfor use on cellulose fibers, wool, and nylon. Their robust resistance to light, washing, and rubbing makes them suitable for demanding textile finishing and printing, delivering lasting and vivid results.

FAQs of Reactive Dyes:

Q: How should reactive dyes be stored to ensure maximum shelf life?

A: Reactive dyes must be kept in a cool, dry place, shielded from direct sunlight and moisture. Storing them in tightly sealed HDPE bags with inner liners extends their shelf life up to 24 months under proper conditions.Q: What is the recommended process for applying reactive dyes to textiles?

A: Reactive dyes can be used via exhaust, pad, or printing methods depending on fiber type and desired outcome. They are well-suited for cellulose fibers like cotton and viscose, as well as wool and nylon, providing vibrant and durable coloration.Q: What safety precautions are necessary when handling reactive dyes?

A: During handling, users should wear gloves and masks to avoid skin contact and inhalation of dye dust. Proper protective gear reduces health risks and ensures a safe working environment.Q: Where are reactive dyes commonly used?

A: Reactive dyes are primarily used in textile dyeing and printing industries, suitable for manufacturing garments, fabrics, and other products from cotton, viscose, wool, or nylon materials.Q: What are the main benefits of using reactive dyes for textile applications?

A: Reactive dyes deliver excellent color fastness to light, washing, and rubbing, maintain low moisture content, and offer brilliant color shades with high purity. Their superior solubility and resistance make them ideal for high-quality textiles.Q: Can the packaging size of reactive dyes be customized for specific client needs?

A: Yes, packaging sizesincluding standard 25 kg HDPE bags and Jumbo bagscan be customized according to client requirements, accommodating both small and large-scale operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Multi Color Reactive Dyes

Price 60 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solubility : Easily Soluble in Water

Physical Form : Powder

Purity : 99% Min

Application : Other, Cellulose Fabrics, Cotton, Viscose, Linen, Silk, Blended Fabrics

M Cold Series Reactive Dyes

Price 65 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solubility : Easily soluble in water

Physical Form : Powder

Purity : 99% Minimum

Application : Other, Cellulosic fibers such as cotton, viscose, linen; textile industry

Reactive Yellow MG

Price 65 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solubility : Soluble in Water

Physical Form : Powder

Purity : >98%

Application : Other, Textile Industry, Fabric Dyeing, Cotton, Silk, Wool, Leather

Bi Functional ME Series Dyes

Price 70 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solubility : Soluble in Water

Physical Form : Other, Powder/Granular

Purity : >98%

Application : Other, Cellulosic Fibers (Cotton, Viscose, etc.)

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry