Purple H3R Reactive Dyes

Price 50 INR/ Kilograms

Purple H3R Reactive Dyes Specification

- Poisonous

- Non-poisonous

- Solvent Color

- Purple

- Shape

- Powdered

- Resistance

- Excellent light, washing, perspiration resistance

- Other Names

- Reactive Violet H3R, C.I. Reactive Violet 5

- Melting Point

- Decomposes before melting

- Shelf Life

- 24 months in original sealed pack

- Density

- 0.90 Gram per cubic centimeter(g/cm3)

- Application

- Cellulosic fibers such as cotton, viscose, linen, and blends

- Purity

- 99% min.

- Ph Level

- 6-8 (1% solution)

- Molecular Formula

- C20H17ClN6Na4O12S4

- HS Code

- 32041600

- Structural Formula

- Available on request

- Taste

- Odorless

- Strength

- Standard, 100%

- Rubbing Resistance

- Good dry and wet

- Grade

- Industrial Grade

- Moisture (%)

- Max 2%

- Water Resistance

- Excellent

- Solubility

- Soluble in water

- Size

- Customizable packaging (25kg bags/drums/totes)

- Smell

- Odorless

- CAS No

- 93050-80-7

- Type

- Reactive Dye

- Usage

- Textile Dyeing, Printing, Industrial Application

- Physical Form

- Powder

Purple H3R Reactive Dyes Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

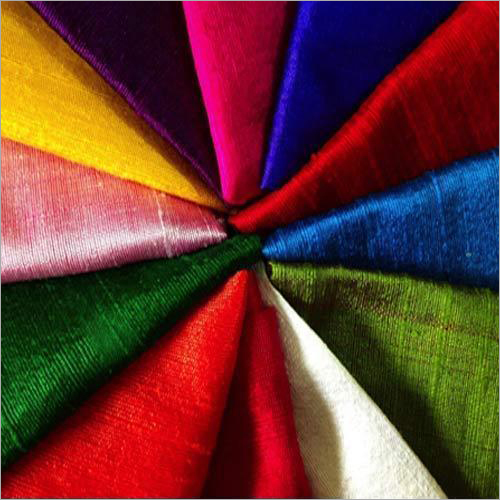

About Purple H3R Reactive Dyes

Superior Fastness for Long-Lasting Results

Purple H3R Reactive Dyes stand out for their exceptional fastness properties, including strong resistance to washing, perspiration, rubbing, and exposure to light. This ensures textiles retain their rich, vibrant hues and resist fading even after repeated laundering or exposure to environmental factors. Utilizing these dyes leads to high-quality, durable finished goods.

Versatile Application Methods

Tailored for modern dyeing techniques, Purple H3R Reactive Dyes are compatible with exhaust, pad, and print methods. This versatility simplifies integration into existing workflow processes and allows textile manufacturers to achieve precise and consistent coloration across various fiber compositions and product lines.

Safe, Stable, and Convenient Packaging

With a stability of up to 24 months in original sealed packs and non-poisonous, odorless qualities, these dyes support safe and effective material handling. Available in HDPE bags with inner liners or customizable bulk packaging, they are convenient for manufacturers, dealers, and exporters. Recommended storage in cool, dry places ensures reliability throughout their shelf life.

FAQ's of Purple H3R Reactive Dyes:

Q: How can Purple H3R Reactive Dyes be applied to fabrics?

A: Purple H3R Reactive Dyes are designed for use with cellulosic fibers like cotton, viscose, and linen. You can apply these dyes using exhaust, pad, or print dyeing methods, making them suitable for a range of industrial and textile processes.Q: What benefits do Purple H3R Reactive Dyes offer for textile manufacturers?

A: These dyes provide excellent wash, light, and perspiration fastness, ensuring that colors remain vivid and resistant to fading. Their compatibility with modern dyeing techniques and high purity (99% min.) contribute to consistent quality and cost-effective operations.Q: When is the best time to use Purple H3R Reactive Dyes in the textile process?

A: Purple H3R Reactive Dyes should be used during the dyeing or printing stages of textile processing, particularly when working with cellulosic materials such as cotton fabrics, viscose blends, or linen products to achieve long-lasting, rich purple shades.Q: Where should Purple H3R Reactive Dyes be stored to maintain stability?

A: For optimal stability, store these dyes in tightly sealed original packaging, in a cool and dry place away from direct sunlight. Following these storage guidelines helps maintain their shelf life of up to 24 months.Q: What is the recommended process for using Purple H3R Reactive Dyes in textile applications?

A: Dissolve the dye in water and apply to the fabric using the chosen method (exhaust, pad, or print). Adjust pH to 6-8 as required, and follow appropriate fixation and washing steps to achieve strong dye-fiber bonding and ensure fastness properties.Q: Are there customizable options for the packaging of Purple H3R Reactive Dyes?

A: Yes, Purple H3R Reactive Dyes are available in customizable packaging options, including standard 25kg HDPE bags with inner liners, drums, and totes to accommodate specific requirements of manufacturers and exporters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Reactive Dyes Yellow 7

Price 70 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solvent Color : Yellow

Purity : 99%

Application : Other, Cotton, Wool, Silk, Polyester Blends

Solubility : Soluble in Water

Highly Exhausted Reactive Dyes

Price 75 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solvent Color : Various (Based on Dye Shade)

Purity : 99.5% Min

Application : Other, Cotton, Viscose, Linen, Blended Fabrics, Textile Industries

Solubility : Soluble in Water

Yellow Color Reactive Dyes

Price 90 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solvent Color : Bright Yellow

Purity : 98% Min

Application : Other, Cellulosic fibers (Cotton, Viscose), Wool, Silk

Solubility : Soluble in water

H Cold Series Reactive Dyes

Price 85 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solvent Color : Consistent with shade

Purity : >98%

Application : Other, Cellulosic fibers such as cotton, viscose, and blended fabrics

Solubility : Highly soluble in water

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry