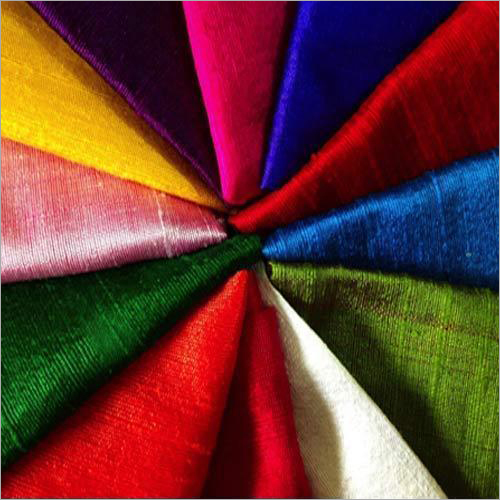

Industrial Reactive Dyes

Price 55 INR/ Kilograms

Industrial Reactive Dyes Specification

- HS Code

- 32041600

- Purity

- 99% Min.

- Density

- 1.2 Gram per cubic centimeter(g/cm3)

- Shape

- Powder / Granule

- Size

- Customizable

- Smell

- Odorless

- Shelf Life

- 24 Months

- Rubbing Resistance

- Good

- Taste

- Odorless / Tasteless

- Water Resistance

- Excellent

- Application

- For Dyeing and Printing Cellulosic Fibers

- Strength

- High Tinctorial Strength

- Solvent Color

- Bright shade as per requirement

- Structural Formula

- Varies (depending on dye)

- Molecular Formula

- Varies (depending on dye type)

- Grade

- Industrial Grade

- Poisonous

- NO

- Resistance

- Good Light and Washing Fastness

- Other Names

- Fiber Reactive Dye

- Solubility

- Easily soluble in water

- CAS No

- None

- Type

- Industrial Reactive Dye

- Usage

- Textile Industry, Leather Industry, Paper Industry, Dyeing, Printing

- EINECS No

- None

- Physical Form

- Powder / Granular

Industrial Reactive Dyes Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

About Industrial Reactive Dyes

A few notable features of ED Type Dyes are :

- Ideal for high exhaustion dyeing

- Works for darker shades

- Good leveling and fastness properties

- Outstanding reproducibility

- Low effluent load as it contains less chemical

Application : ED Type Dyes are suitable for fabric dyeing.

MOQ 50kg:

| SHADES | PRODUCTS | C. I. NAME | CAS NO. |

|---|---|---|---|

| Yellow ED-2G | NA | ||

| Yellow ED | NA | ||

| Orange ED-2R | NA | ||

| Red ED | NA | ||

| Red ED-3B | NA | ||

| Red ED-7B | NA | ||

| Blue ED | NA | ||

| Navy Blue ED | NA | ||

| Black ED | NA | ||

| Black EDG | NA | ||

| Black EDR | NA |

High pH Stability for Reliable Operation

These industrial reactive dyes remain stable in the pH range of 5 to 9, which is crucial for uninterrupted dyeing processes. Their reliability ensures consistent color development without unexpected shifts, suiting both batch and continuous dyeing operations.

Superior Compatibility & Low Staining

Extensively tested, these dyes exhibit compatibility with most dyeing auxiliaries used in cellulosic fiber processing. Their low staining on hardware reduces maintenance needs and helps keep machinery in optimal condition, improving production efficiency.

Safe, Convenient Packaging & Long Shelf Life

Packaged in 25kg and 50kg HDPE bags with inner liners, the dyes are protected from moisture and contaminants. With a shelf life of 24 months, storing these dyes in a cool, dry place away from sunlight ensures maximum effectiveness and safety over time.

FAQs of Industrial Reactive Dyes:

Q: How should Industrial Reactive Dyes be stored for optimal shelf life?

A: To ensure a shelf life of up to 24 months, store the reactive dyes in a cool, dry location away from direct sunlight. HDPE bags with inner liners protect the dyes from moisture and contamination, preserving their quality.Q: What are the benefits of using these dyes for textile and leather applications?

A: These dyes offer high tinctorial strength, excellent water and light resistance, and stable performance across a pH range of 5 to 9. They ensure bright shades, minimal staining on hardware, and compatibility with most dyeing auxiliaries, resulting in efficient and vivid dyeing.Q: When should these dyes be used in the dyeing and printing process?

A: Apply the dyes during the dyeing or printing of cellulosic fibers in the textile, leather, or paper industries. Their stable pH profile and dispersibility make them ideal for both continuous and batch operations, ensuring consistent results at various process stages.Q: Where are these dyes primarily applied?

A: Industrial Reactive Dyes are mainly utilized in the textile industry, but they are also suitable for leather and paper dyeing and printing. They specifically target cellulosic fibers, offering reliable coloration for a wide range of industrial applications.Q: What is the process for using these dyes in dyeing operations?

A: Dissolve the dye in water for excellent dispersibility, then add to the dye bath with the required auxiliaries. Maintain the process pH between 5 and 9 for optimal stability and interaction. The dyes, being anionic, perform effectively throughout standard industrial protocols.Q: How do these dyes contribute to operational safety?

A: The dyes contain heavy metals below permissible limits, are odorless, non-poisonous, and low-staining, ensuring user and equipment safety. Secure packaging and compatibility further help maintain a safe, efficient working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Reactive Yellow M4R

Price 85 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Physical Form : Powder

Purity : 99% Min

Usage : Other, Synthetic Textile Dye

Solubility : Soluble in Water

H Cold Series Reactive Dyes

Price 85 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Physical Form : Powder

Purity : >98%

Usage : Other, Textile dyeing and printing

Solubility : Highly soluble in water

Liquid Reactive Dyes

Price 60 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Physical Form : Liquid

Purity : >98%

Usage : Other, Textile Dyeing and Printing

Solubility : Completely Soluble in Water

Reactive Yellow MG

Price 65 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Physical Form : Powder

Purity : >98%

Usage : Textile Dyestuffs

Solubility : Soluble in Water

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry