Bi Functional ME Series Reactive Dyes

Price 85 INR/ Kilograms

Bi Functional ME Series Reactive Dyes Specification

- Water Resistance

- High

- Resistance

- Excellent washing, light, perspiration, and rubbing fastness

- Density

- 1.20 Gram per cubic centimeter(g/cm3)

- Moisture (%)

- Max 2.0%

- Rubbing Resistance

- Excellent

- Structural Formula

- Available upon request

- Taste

- Odorless

- Solubility

- Completely soluble in water

- Shelf Life

- 2 years under recommended storage

- Strength

- Standardized (as per shade requirement)

- Grade

- ME Series

- Application

- Cellulosic fibers (cotton, viscose, linen, etc.)

- Other Names

- Bi-Functional ME Reactive Dye

- HS Code

- 32041600

- Melting Point

- Decomposes

- Size

- Custom packing: 25 Kg / 50 Kg bags, barrels

- Solvent Color

- Characteristic to shade

- Purity

- Standard Commercial Grade (approx. 98%)

- Smell

- Odorless

- Molecular Formula

- Varies by color shade

- Shape

- Solid / Powder

- Ph Level

- 6 8 (1% solution in water)

- Poisonous

- NO

- CAS No

- Various (product range specific)

- Type

- Reactive Dye

- Usage

- Textile Dyeing and Printing

- EINECS No

- Available on request

- Physical Form

- Powder / Granular

- Stability

- Stable under normal storage conditions

- Salt/Alkali Requirement

- Requires salt and alkali for fixation

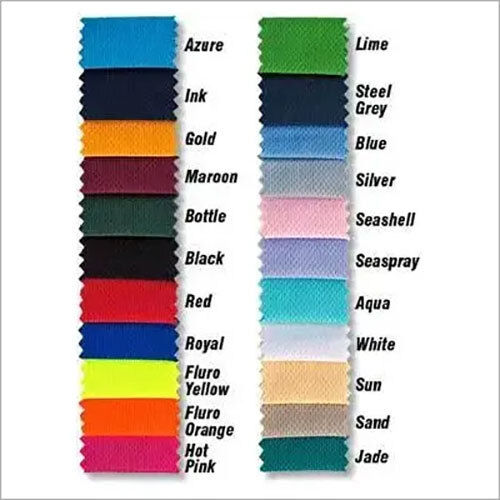

- Color Range

- Wide spectrum including reds, yellows, blues, blacks, etc.

- Storage Conditions

- Cool, dry place, away from sunlight

- Compatibility

- Compatible with exhaust and pad dyeing methods

- Dyeing Temperature

- Recommended 60C 80C

- Reactive Groups

- Vinylsulphone and monochlorotriazine

- Dyeing Method

- Exhaust, cold pad-batch, continuous, semi-continuous

- Dye Class

- Bifunctional (contains two reactive groups)

- Commercial Availability

- Bulk supply for industrial use

Bi Functional ME Series Reactive Dyes Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

About Bi Functional ME Series Reactive Dyes

Specification

| PRODUCTS | C. I. NAME | CAS NO. |

| Yellow ME4GL | Yellow 160A | 129898-77-7 |

| G.Yellow MERL | Yellow 145 | 93050-80-7 |

| Orange ME2RL | Orange 122 | 79809-27-1 |

| Red ME3BL | Red 194 | |

| Red ME4BL | Red 195 | 93050-79-4 |

| Red ME6BL | Red 196/250 | |

| Red MERBL | Red 198 | 145017-98-7 |

| Red ME3BN | Red 180 | 72828-03-6 |

| Red ME3GL | Red 223 | |

| N. Blue ME2GL | Blue 194 | 93050-78-3 |

| N.Blue BRF | Blue 221 | |

| Blue BF | Blue 222 | |

| Blue ME2RL | Blue 248 | |

| Black MEGR | | |

| Black HFGR | | |

Versatile Application Methods

Bi Functional ME Series Reactive Dyes adapt easily to multiple textile processes, including exhaust, cold pad-batch, continuous, and semi-continuous dyeing. Their compatibility with both exhaust and pad dyeing methods allows manufacturers flexibility while achieving consistent shade and superior penetration for cellulosic fabrics.

Reliable Performance and Fastness

These dyes are engineered for high wash, light, perspiration, and rubbing fastness, preserving vibrant colors even under rigorous conditions. Their standardized strength and high solubility mean they deliver predictable, uniform results, reducing reprocessing and ensuring quality textiles every time.

Safe Storage and Handling

Supplied as odorless, solid powder or granules, Bi Functional ME Reactive Dyes should be stored in a cool, dry place away from direct sunlight. Under recommended conditions, their potency remains stable for up to two years. Custom packaging supports bulk supply, meeting the needs of dealers, exporters, and manufacturers.

FAQ's of Bi Functional ME Series Reactive Dyes:

Q: How are Bi Functional ME Series Reactive Dyes applied in textile processing?

A: These dyes are compatible with exhaust, cold pad-batch, continuous, and semi-continuous dyeing methods. Apply them to cellulosic fibers such as cotton, viscose, or linen, ensuring the use of required salt and alkali for effective fixation at recommended temperatures (60C - 80C).Q: What benefits do bifunctional reactive groups offer to these dyes?

A: The presence of both vinylsulphone and monochlorotriazine groups enables strong chemical bonding with fibres, resulting in brighter shades, improved fixation, and excellent resistance to washing, light, and rubbing.Q: When should salt and alkali be added during the dyeing process?

A: Salt and alkali should be introduced during the dyeing stage as they facilitate dye fixation onto the fiber. Proper timing and quantity optimize color yield and ensure high fastness properties.Q: Where should Bi Functional ME Reactive Dyes be stored for maximum shelf life?

A: Keep the dyes in a cool, dry environment away from sunlight. When stored under these recommended conditions, the dyes maintain their performance and potency for up to two years.Q: What makes these dyes suitable for industrial bulk use?

A: The dyes are stable, offered in large custom packaging (25 kg/50 kg), and standardized for consistent quality, making them ideal for bulk textile dyeing applications by dealers, exporters, and manufacturers.Q: How does the solubility of these dyes affect the dyeing process?

A: Their complete solubility in water ensures uniform dispersion and penetration into fibers, resulting in even, vibrant coloring without patchiness or residue.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Reactive Dye Yellow 22

Price 100 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solubility : Soluble in water

Shelf Life : 2 Years

Strength : Highly concentrated

Physical Form : Powder

Yellow Color Reactive Dyes

Price 90 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solubility : Soluble in water

Shelf Life : 24 months

Strength : 100% Standard

Physical Form : Powder

REACTIVE YELLOW M3R

Price 85 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solubility : Easily soluble in water

Shelf Life : 2 Years

Strength : 100%

Physical Form : Powder

Direct Reactive Dye

Price 90 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solubility : Soluble in Water

Shelf Life : 2 Years

Strength : High Tinting Strength

Physical Form : Powder

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry