Para Phenyldiamine

Price 90 INR/ Kilograms

Para Phenyldiamine Specification

- Rubbing Resistance

- Good

- Solvent Color

- Colorless or Slightly Brown

- Solubility

- Soluble in water, ethanol, and ether

- Moisture (%)

- 0.5%

- Application

- Other

- HS Code

- 29215119

- Smell

- Amine-Like

- Taste

- Bitter

- Purity

- 99% Min

- Poisonous

- YES

- Other Names

- PPD, 1,4-Diaminobenzene, p-Phenylenediamine

- Strength

- High Reactivity

- Ph Level

- 7 (neutral in solution)

- Shelf Life

- 2 Years Years

- Melting Point

- 137-140C

- Water Resistance

- Moderate

- Shape

- Granules or Powder

- Boiling point

- 267C

- Density

- 1.16 Gram per cubic centimeter(g/cm3)

- Structural Formula

- C6H4(NH2)2

- Resistance

- Other

- Grade

- Industrial Grade

- Size

- Standard Industrial Grade

- Molecular Formula

- C6H8N2

- CAS No

- 106-50-3

- Type

- Chemical

- Usage

- Other

- EINECS No

- 203-404-7

- Physical Form

- Crystalline Solid

- Compatibility

- Incompatible with strong oxidizing agents

- Appearance

- White to light purple gray solid

- Refractive Index

- Not applicable (solid)

- Flash Point

- 171C

- Free Amine Content

- 0.5%

- Autoignition Temperature

- Not determined

- Storage Conditions

- Store in tightly closed container, away from light and moisture

- UN Number

- 1673

- Molecular Weight

- 108.14 g/mol

- Hazard Class

- 6.1 (Toxic Substances)

- Packaging

- 25 kg HDPE drum or as required

Para Phenyldiamine Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

About Para Phenyldiamine

Para Phenyldiamine:-

Our company is listed as a leading manufacturer and exporter of high quality Para Phenyldiamine which are used for manufacturing cosmetic and dye intermediates. We use the best grade raw materials sourced from trusted vendors who ensure uninterrupted supply. Available in 100% purity with negligible moisture content in the powdered form, Para Phenyldiamine appears as white color crystal with a flashpoint of 155 degrees Celsius. This is a high grade compound manufactured to meet the requirements by our national and international clients. We offer the product in suitable packs as per the demands by our customers.

Features of Para Phenyldiamine:

- Accurate composition

- Good for use in manufacturing cosmetic products

- Harmless in application

- Availability in various packing options

MOQ 50kg

| Specifications of Para Phenyldiamine : | |

|---|---|

| Chemical Name | Para Phenylene Diamine |

| Synonym | Para Diamino Benzene Para Amino Aniline |

| CAS No. | 106-50-3 |

| Molecular Weight | 108 GM/Mole |

| Molecular Formula | C6 H8 N2 |

| Structural Formula | H2N-- ----NH2 |

| Melting Point | 139.5-141.50 C |

| Purity | 99.9% min(Organic)/99.5% min (Gravimetric) |

| Flash Point | 155 C |

| Other Insolubles | 0.1 % Max |

| Moisture | 0.2 % Max |

| Form Supplied | Powder |

| Physical Appearance | White color |

| Basis Of Sale | As is Basis |

| Packing | 25/50 Kgs. Bags/Drums |

| Uses | Cosmetics, Dye intermediate etc. |

Product Applications and Functionality

Para Phenylenediamine (PPD) serves essential roles across personal care and chemical industries. Its primary uses include functioning as a dye intermediate in hair colors, as well as in the production of rubber chemicals, cosmetics, and pharmaceuticals. Its excellent color-fastness, solubility, and reactivity make it invaluable for industrial applications where both performance and chemical purity are required.

Safe Handling and Storage Guidelines

PPD must be handled with stringent precautions due to its toxic nature. Always store in a tightly closed container, away from moisture and direct light, to maintain product stability and prevent hazardous exposure. Use proper protective equipment during handling, and follow local and international safety guidelines regarding hazardous substances.

FAQs of Para Phenyldiamine:

Q: How should Para Phenylenediamine (PPD) be stored to maintain its stability?

A: PPD should be stored in a tightly closed container, away from light and moisture, to prevent degradation or hazardous exposure. Ensure the storage area is cool and dry for optimal stability and safety.Q: What are the main uses of Para Phenylenediamine in industry?

A: PPD is predominantly used as a dye intermediate in hair coloring products, as well as in producing rubber chemicals, cosmetics, and pharmaceuticals. Its high reactivity and purity make it suitable for multiple industrial applications.Q: When should protective measures be taken while handling PPD?

A: Protective measures, including gloves, eyewear, and proper ventilation, should always be used when handling PPD, due to its classification as a toxic substance (Hazard Class 6.1). Avoid direct skin and eye contact.Q: Where can Para Phenylenediamine be safely transported or supplied from in India?

A: PPD can be supplied or exported by licensed dealers, exporters, manufactuers, and suppliers in India. Transportation must comply with regulations for hazardous substances, including labeling with UN Number 1673.Q: What is the process of using PPD in hair dye formulations?

A: In hair dye applications, PPD acts as a precursor that reacts with oxidizing agents to create color molecules. Formulations are carefully controlled to limit free amine content and ensure user safety.Q: What are the benefits of using PPD as a dye intermediate?

A: PPD offers excellent color-fastness, rubbing resistance, and solubility, making it highly effective in dyeing applications. It ensures vibrant, long-lasting results in hair and textile dyes.Q: How compatible is PPD with other chemicals during formulation?

A: PPD is incompatible with strong oxidizing agents and should not be mixed with them. Its moderate resistance to water and alkalis supports stable formulation in compatible chemical processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hair Dyes Category

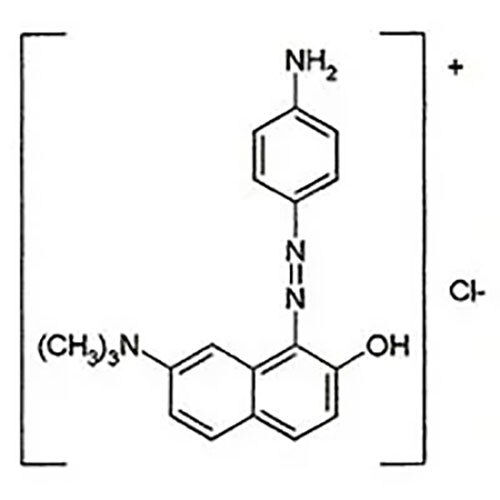

Basic Red 76 Hair Dyes

Price 75 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Application : Other, Used in permanent and semipermanent hair color formulations

Solubility : Soluble in water

CAS No : 68449845

Molecular Formula : C16H19N4Cl

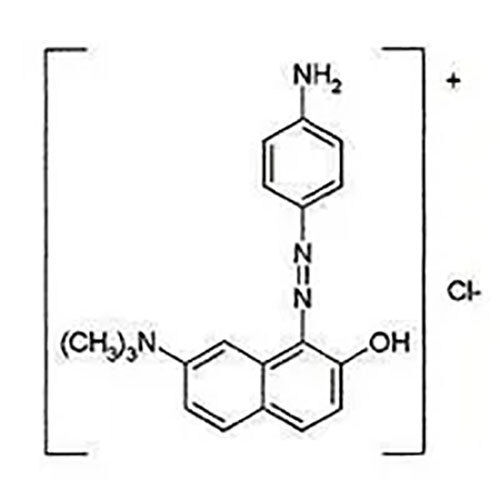

Basic Orange 31 Hair Dye

Price 65 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Application : Other, Hair Coloring

Solubility : Soluble in water

CAS No : 12221942

Molecular Formula : C15H16N5O2

Para Phenyldiamine

Minimum Order Quantity : 500 Kilograms

Application : Industrial

Solubility : In water

CAS No : 106503

Molecular Formula : C6 H8 N2

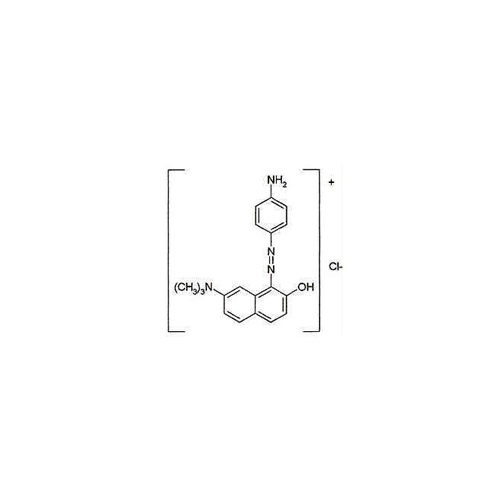

Basic Brown 17

Minimum Order Quantity : 500 Kilograms

Application : Industrial

Solubility : In water

CAS No : 68391 322

Molecular Formula : C19H20N5 O3 Cl

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry