Optimum Quality Direct Dyes

Price 70 INR/ Kilograms

Optimum Quality Direct Dyes Specification

- Resistance

- Good Wash & Light Fastness

- Shelf Life

- 3 Years

- Solubility

- Soluble in Water

- Grade

- Industrial

- Smell

- Odorless

- Strength

- Standardized (100%)

- Structural Formula

- Varies

- Taste

- Odorless

- Solvent Color

- Bright & Uniform

- Melting Point

- Decomposes

- Shape

- Granular

- Application

- Textile Dyestuffs, Paper Industry, Leather Industry, Wood Coloring

- Other Names

- Substantive Dyes

- Water Resistance

- Good

- Purity

- 99% Min

- Density

- 1.2 Gram per cubic centimeter(g/cm3)

- HS Code

- 3204

- Molecular Formula

- Varies (dependent on color series)

- Size

- Fine Powder

- Moisture (%)

- Less than 1%

- Rubbing Resistance

- Good

- Type

- Direct Dye

- Usage

- For Textile Industry, Paper & Leather Dyeing, Wood, Silk, Jute, etc.

- Physical Form

- Powder

- pH Stability

- Stable in Neutral to Slightly Alkaline Medium

- Storage Condition

- Keep in Cool and Dry Place

- Dispersibility

- Excellent

- Stability

- Stable under recommended storage conditions

- Packaging Type

- Plastic Drum, Bag, Box

- Fineness

- Super Fine

- Color Range

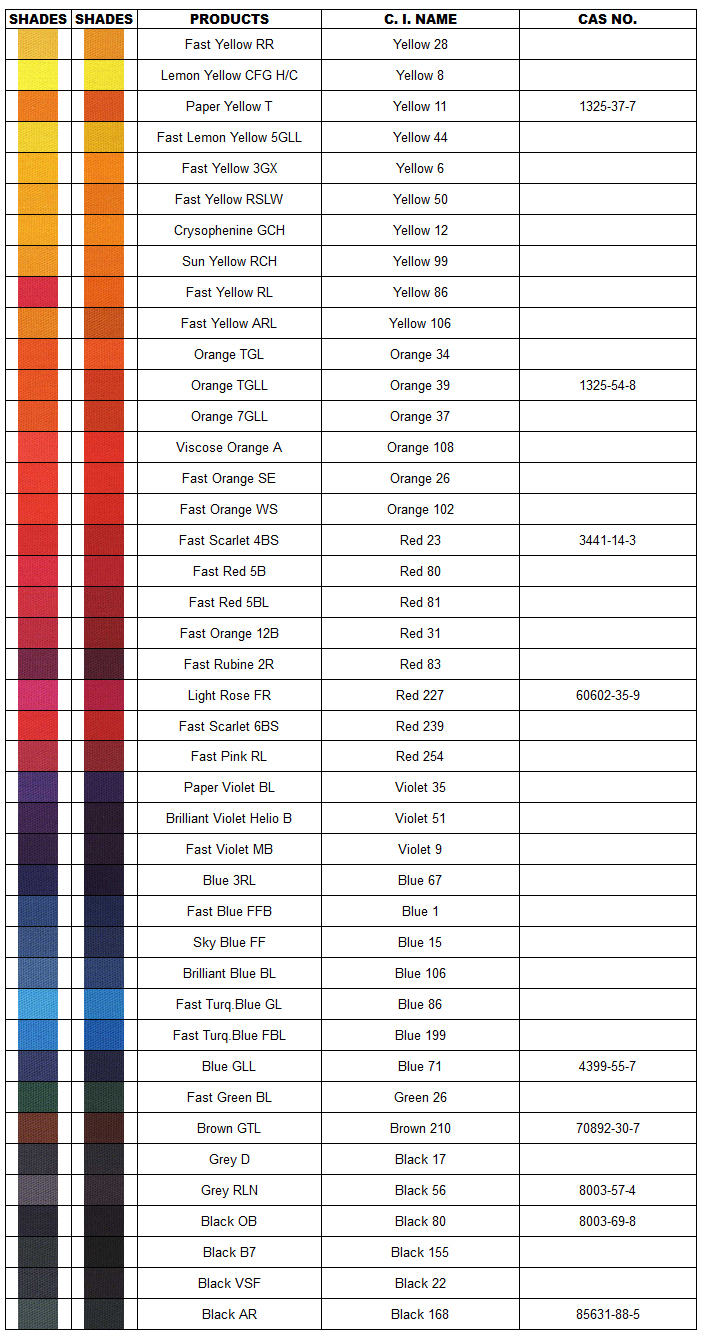

- Red, Orange, Blue, Yellow, Black, etc.

- Heat Stability

- Moderate

Optimum Quality Direct Dyes Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

About Optimum Quality Direct Dyes

Direct Dyes: Dyes for Textile Industries

Classification of the Optimum Quality Direct Dyesin Colour Index system mentions to different planar, highly conjugated molecular structures containing one or more group of anionic sulfonate. Due to this reason the molecules are soluble in water. Though, many direct dyes can be received in powder form, it is growingly popular to obtain them as liquid concentrates. The concentrates are easy to manage and meter.

The Direct Dyes are utilized for cellulose fibres such as cotton, linen & rayon. Some dyes in this class are more lightfast than similar colors of fibre reactive dyes. With respect to washfastness, all the direct dyes work rather poorly. Without a proper after-treatment the direct dyes bleed a little with every wash; they lose brightness and damaging other clothing washed in the same load.

There are some specific after-treatments which can be used to figure out this problem. A product called Retayne, acts well to make fabric washable dyed with the direct dyes, without any bleed of the dye. The Retayne is an ionic bulking agent which basically glues the dye into the fibre.

Direct Dye and Its Impact on the Environment

Process of dyeing with direct dyes is very easy. These are a class of dyestuffs applied directly to the substrate in an alkaline or neutral bath. They provide full shades on linen or cotton without mordanting, and can be applied to silk, rayon and wool also.

Products Features:

- Non-Caustic, Excellent Fastness Properties, Accurate Composition,Balanced Composition

- Safe For Use, Good Solubility Properties, Longer Shelf Life, Good Heat Stability

- Excellent Fastness Properties, High Tinting Strength,Dyes Are Non-Caustic, Highly Concentrated

- Ensure Qualitative Results, Free From Impurities, Free From Moisture

Why you Choose Our Product?

- Trusted Production Technology is used in Direct Dyes Manufacturing

- Direct Dyes offered by us are Cost-Effective

- Megha International used a Have a supporting equipment in our R&D unit

- For stock of dyes products & its raw materials we have warehouse too

- Our excellent quality control lab with Separate drying & packing areas for Direct Dyes.

Direct Dyes : Choose Variety of Direct Dyes from Our Collection?

Exceptional Color Range for Versatile Applications

Our direct dyes span intense shades of red, orange, blue, yellow, and black, suitable for textiles, paper, leather, wood, silk, and jute. Designed to deliver brilliant, uniform coloring, their formulation adapts seamlessly to varied industrial processes while ensuring vibrant outcomes across different materials.

Superior Quality with Stability and Safety

Packaged in durable drums, bags, or boxes, these dyes remain stable under recommended cool, dry storage conditions. Their excellent dispersibility and superfine granularity guarantee uniform application, while their odorless characteristic and standardized purity ensure safety and ease of handling in industrial environments.

Efficiency and Reliability in Industrial Dyeing

Optimum Quality Direct Dyes are engineered for consistent, long-lasting performance. Boasting stable pH, solid resistance to washing, light, and rubbing, and bright solvent colors, they help optimize manufacturing processes by reducing re-dyeing, lowering waste, and maintaining finished product quality over time.

FAQs of Optimum Quality Direct Dyes:

Q: How should Optimum Quality Direct Dyes be stored to prolong shelf life?

A: Store the dyes in cool, dry conditions and use the original plastic drum, bag, or box packaging. This prevents moisture absorption and maintains their stability and effectiveness for up to three years.Q: What is the recommended method for dissolving and applying these dyes?

A: These dyes are water-soluble and disperse excellently. Simply add to water and stir until fully dissolved, ensuring a uniform and bright color for textile, paper, leather, wood, silk, or jute applications.Q: When is the best time to use these dyes during manufacturing?

A: Optimum Quality Direct Dyes should be used during the coloring or dyeing phase after preparing the substrate. Their stable pH and moderate heat stability allow reliable integration into various industrial dyeing processes.Q: Where can the dyes be applied beyond textiles?

A: Aside from textiles, these direct dyes are suitable for paper, leather, wood, silk, and jute dyeing processes. They demonstrate good wash and light fastness, making them ideal for products requiring lasting color quality.Q: What benefits do Optimum Quality Direct Dyes offer manufacturers?

A: Manufacturers benefit from standardized strength, high purity, superfine granularity, and odorless formulation. These qualities ensure consistent, uniform results while minimizing process waste and maximizing finished product longevity.Q: How does the dyes resistance to washing and light impact finished goods?

A: Good wash and light fastness guarantee that dyed products retain their vibrant color even after repeated washing and exposure to light, supporting durability and premium product standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Direct Dyes Category

Lemon Chrome Pigment

Price 85 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solubility : Insoluble in Water

Physical Form : Powder

Usage : Other, Pigment for paints, plastics, inks, coatings

Purity : 99%

Direct Black

Price 75 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solubility : Soluble in water

Physical Form : Powder

Usage : Other, Textile Dyeing, Paper Printing

Purity : 98%

Direct Black Dyes

Price 100 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solubility : Easily soluble in water

Physical Form : Powder

Usage : Textile Dyestuffs

Purity : 98% Min

Direct Dyes

Price 50 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solubility : Soluble in Water

Physical Form : Powder

Usage : Other, Textile Dyeing, Paper Dyeing, Leather Dyeing, Wood Staining, Ink Manufacturing

Purity : 98% Min

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry