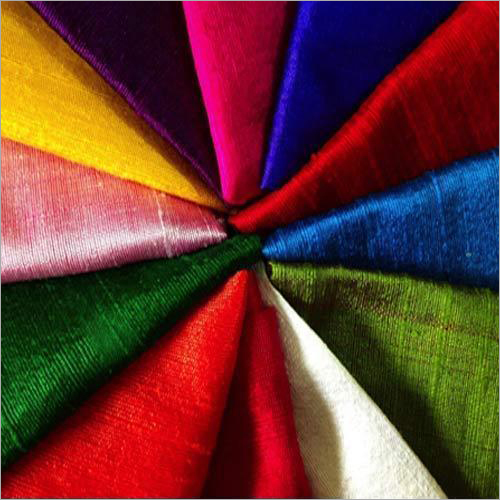

Multi Color Reactive Dyes

Price 60 INR/ Kilograms

Multi Color Reactive Dyes Specification

- Melting Point

- Decomposes

- Shelf Life

- 2 Years

- Strength

- Highly Concentrated

- Smell

- Odorless

- HS Code

- 32041600

- Resistance

- Excellent Fastness to Washing, Chlorine and Light

- Moisture (%)

- Less than 1.5%

- Other Names

- Multicolor Reactive Dyes

- Purity

- 99% Min

- Structural Formula

- Varies

- Grade

- Industrial Grade

- Solubility

- Easily Soluble in Water

- Shape

- Powdered

- Density

- 1.2 Gram per cubic centimeter(g/cm3)

- Application

- Cellulose Fabrics, Cotton, Viscose, Linen, Silk, Blended Fabrics

- Poisonous

- NO

- Rubbing Resistance

- Excellent

- Taste

- Odorless

- Solvent Color

- Varies (Bright/Multicolor)

- Water Resistance

- Excellent

- Type

- Reactive Dye

- Usage

- Textile Dyeing and Printing

- Physical Form

- Powder

- Storage Conditions

- Store in Cool, Dry Place, Away from Direct Sunlight

- Packaging Size

- 25 kg HDPE bags

- Compatibility With Auxiliaries

- Compatible with All Dyeing Auxiliaries

- Eco-Friendly

- Yes, Azo Free Dyes

- Dispersibility

- Excellent

- Stability

- Stable Under Normal Storage Conditions

- Colour Shades Available

- Wide Range of Multicolor Shades

- Chemical Class

- Vinyl Sulphone, MCT, HE type Reactive Dyes

- CI Name

- Varies by Shade

- Ionic Nature

- Anionic

- Certified Quality

- ISO 9001:2015 Compliant

- Compatibility

- Suitable with Exhaust, Cold Pad Batch, Printing, and Continuous Dyeing Methods

Multi Color Reactive Dyes Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, North America

- Main Domestic Market

- All India

About Multi Color Reactive Dyes

A few of the remarkable features of LX Type Dyes are:

- Non-dusting due to liquid

- Get easily mixed with water in any ratio

- Ideal for dyeing wet polyacrlonitrile thread

- Good wash off property

Application: LX Type Dyes are idea for dyeing wet polyacrlonitrile thread.

MOQ :50kg

| SHADES | PRODUCTS | C. I. NAME | CAS NO. |

|---|---|---|---|

| Yellow LX | NA | ||

| Red LX | NA | ||

| Blue LX | NA | ||

| Red LX2B | NA | ||

| Navy LX | NA |

Versatile Dyeing Methods

Our Multi Color Reactive Dyes are compatible with various application processes including exhaust, cold pad batch, printing, and continuous dyeing, enabling flexibility for manufacturers. These dyes disperse excellently, ensuring uniform and vibrant color results after each batch. Their adaptability makes them an ideal choice for diverse plant setups and production scales.

Eco-Friendly & Certified Quality

Formulated to be Azo-free and meeting ISO 9001:2015 certification, these dyes prioritize environmental safety without compromising on performance. Suitable for eco-conscious brands, they offer high standards of purity and safety for operators and finished textiles alike, with a shelf life reaching up to two years under proper storage.

Exceptional Performance & Stability

With high purity (minimum 99%), these dyes display outstanding resistance to washing, chlorine, light, and rubbing. Their anionic nature makes them suitable for cellulose-based fibers like cotton, linen, and viscose. Even after exposure to moisture or water, color brilliance and fastness are retained, offering reliability in finished products.

FAQs of Multi Color Reactive Dyes:

Q: How should Multi Color Reactive Dyes be stored to maintain their quality?

A: Multi Color Reactive Dyes should be stored in a cool, dry place away from direct sunlight. They are stable under normal storage conditions, and with moisture content below 1.5%, their shelf life is up to two years if properly stored.Q: What application processes are these dyes suitable for?

A: These dyes are compatible with exhaust, cold pad batch, printing, and continuous dyeing methods, offering flexibility for different textile production lines and ensuring vibrant, uniform coloration across processes.Q: When is it most beneficial to use these dyes in textile manufacturing?

A: It is ideal to use these dyes when working with cellulose-based fabrics such as cotton, linen, viscose, silk, and blended textiles. Their excellent dispersibility and high concentration yield superior color fastness and brilliance, especially important during large-scale or demanding dyeing sessions.Q: What benefits do these reactive dyes offer compared to traditional options?

A: These reactive dyes ensure excellent fastness to washing, rubbing, chlorine, and light, making the colors durable and fade-resistant. They are also eco-friendly (Azo-free), ISO 9001:2015 certified, and compatible with all dyeing auxiliaries, supporting sustainable and high-quality textile production.Q: Where are Multi Color Reactive Dyes commonly applied?

A: Primarily used in the textile industry across India and globally, these dyes are favored by manufacturers, exporters, suppliers, and dealers for dyeing and printing on a wide range of cellulose and blended fabrics.Q: What supports the eco-friendly nature of these dyes?

A: The dyes are crafted to be Azo-free and comply with stringent environmental standards, as evidenced by ISO 9001:2015 certification. This ensures minimal environmental impact and safer handling throughout the dyeing and finishing processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Highly Exhausted Reactive Dyes

Price 75 INR / Kilograms

Minimum Order Quantity : 500 Kilograms, ,

Solvent Color : Various (Based on Dye Shade)

Physical Form : Other, Powder, Granules

Solubility : Soluble in Water

Application : Other, Cotton, Viscose, Linen, Blended Fabrics, Textile Industries

Purple H3R Reactive Dyes

Price 50 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solvent Color : Purple

Physical Form : Powder

Solubility : Soluble in water

Application : Other, Cellulosic fibers such as cotton, viscose, linen, and blends

H Cold Series Reactive Dyes

Price 85 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solvent Color : Consistent with shade

Physical Form : Powder

Solubility : Highly soluble in water

Application : Other, Cellulosic fibers such as cotton, viscose, and blended fabrics

Liquid Reactive Dyes

Price 60 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Solvent Color : Clear to Vivid Color (Depends on Shade)

Physical Form : Liquid

Solubility : Completely Soluble in Water

Application : Other, Cotton, Viscose, Silk, Blends, Yarn and Fabric Dyeing

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry