Direct Reactive Dye

Price 90 INR/ Kilograms

Direct Reactive Dye Specification

- Moisture (%)

- Less than 2%

- Shape

- Powder

- Taste

- Odourless

- Solubility

- Soluble in Water

- Application

- For Dyeing Cotton & Cellulosic Fibres

- Other Names

- Direct Reactive Dye

- Water Resistance

- Yes

- Purity

- 99%

- Resistance

- Good Light & Washing Fastness

- Solvent Color

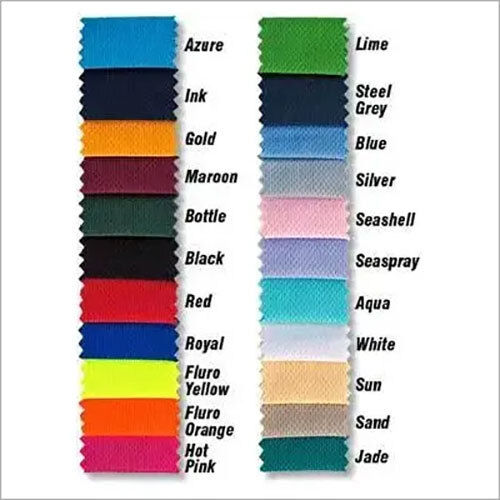

- Bright Shade

- Shelf Life

- 2 Years

- Rubbing Resistance

- Good

- Size

- Customizable

- Strength

- High Tinting Strength

- Poisonous

- NO

- Structural Formula

- None specified

- Density

- Gram per cubic centimeter(g/cm3)

- Molecular Formula

- None specified

- Smell

- Odourless

- HS Code

- 32041600

- Boiling point

- None specified

- Melting Point

- None specified

- Grade

- Industrial Grade

- CAS No

- None specified

- Type

- Reactive Dye

- Usage

- Textile Industry

- EINECS No

- None specified

- Physical Form

- Powder

- Storage Condition

- Store in a cool, dry place

- Stability

- Stable under normal conditions

- Packaging

- 25 kg HDPE Drums/Bags

- Appearance

- Fine Powder

- Ionic Nature

- Anionic

- Eco-Friendly

- Yes

- Compatibility

- Compatible with auxiliaries & fixing agents

Direct Reactive Dye Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Week

- Delivery Time

- 3-7 Days

About Direct Reactive Dye

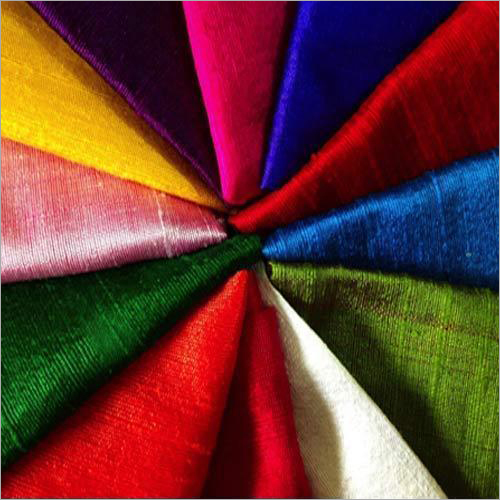

Direct Reactive Dye are series of reactive dyes composed of three color combination. Megha International is the perfect place for purchasing high quality of such type of dyes in bulk quantity. We are the most reliable manufacturer and exporter of Direct Reactive Dye, which are used for dyeing process in textile industry and various other industries. Possessing high exhaustion features, these types of dyes are applicable for medium and deep shades. Available as yellow RR dye, blue RR dye and red RR dye, this dye have excellent wash off properties.

A few notable features of RR Dyes are:

- Works best for deep and medium shades

- Outstanding wash off property

- Uniform fixation

- High exhaustion feature

- Level dyeing

- Three basic components for trichomatic combination

Application : RR Dyes are suitable for dyeing cellulose materials.

FAQs

Why direct dye is not widely used?

Direct colors work best on cellulose strands however they are viable for staining fleece and silk with the expansion of 'saving specialist'. In any case, the wash quickness of the majority of these colors isn't very great however they are better as to the property of light speed. Because of this there is a color drain during each wash.

What is the key factor affecting the dyeing results with direct dyes?

Significant color shower factors that impact the dyeing conduct of direct colors incorporate temperature, season of coloring, liquor ratio, color dissolvability, and presence of electrolyte and different helpers.

How long do direct dyes last?

Preferably, permanent hair colour would remain dynamic always, or possibly until the roots develop. On most heads of hair, that would mean getting a decent 6 two months between final details -however some of the time, even with long-lasting color, variety blur can occur inside half a month.

Exceptional Dyeing Performance

Direct Reactive Dye offers vibrant coloration and superior tinting strength for cotton and cellulosic fibres, making it a dependable choice for textile manufacturers. Its anionic nature allows for uniform dye distribution, and its compatibility with auxiliaries and fixing agents enhances processing flexibility.

Eco-Friendly Industrial Solution

Manufactured to meet environmental standards, this dye is eco-friendly, odourless, and non-poisonous. Its formulated to ensure safety in use while contributing to sustainable textile processes, appealing to industries seeking greener alternatives without sacrificing quality.

Convenient Packaging and Shelf Life

Available in robust 25 kg HDPE drums or bags, Direct Reactive Dye is supplied in a stable, moisture-resistant powder form. With a shelf life of two years and less than 2% moisture content, it assures product longevity, safe storage, and ease of handling for dealers, exporters, manufacturers, and suppliers.

FAQs of Direct Reactive Dye:

Q: How should Direct Reactive Dye be stored to ensure maximum shelf life?

A: To maintain its shelf life of two years, Direct Reactive Dye should be stored in a cool, dry place, preferably in its original 25 kg HDPE drums or bags. Avoid exposure to moisture and direct sunlight to preserve its physical and chemical stability.Q: What is the recommended process for applying Direct Reactive Dye on textiles?

A: Direct Reactive Dye is best applied using standard reactive dyeing procedures optimized for cotton and cellulosic fibres. It can be used with suitable auxiliaries and fixing agents to achieve bright, durable shades with good light and washing fastness.Q: When is Direct Reactive Dye the ideal choice for manufacturers in the textile industry?

A: Manufacturers should choose Direct Reactive Dye when seeking high tinting strength, eco-friendly properties, and reliable color fastness necessary for cotton and cellulosic fibre applications. Its compatibility with various processing agents further facilitates efficient textile production.Q: Where can Direct Reactive Dye be used in textile production?

A: This dye is designed for use in facilities involved in dyeing cotton and cellulosic fibres. Its high solubility in water and adaptable powder form make it suitable for large-scale industrial settings, as well as smaller manufacturing operations across India.Q: What benefits does Direct Reactive Dye offer over conventional dyes?

A: Direct Reactive Dye delivers superior tinting strength, eco-friendliness, and excellent resistance properties such as water, light, and rubbing fastness. Its stable, odourless, and non-poisonous formulation provides enhanced safety and long-term storage convenience.Q: How can users customize the size of Direct Reactive Dye packaging for specific requirements?

A: Users can request customized sizing options in addition to the standard 25 kg HDPE drums or bags. Contact the dealer, exporter, manufacturer, or supplier for tailored packaging solutions to meet specific production or handling needs.Q: What is the usage protocol for Direct Reactive Dye in dyeing cotton and cellulosic fibres?

A: Begin by dissolving the powder in water to prepare a dyebath, then immerse the pre-treated fibres. Employ recommended auxiliaries and fixing agents to enhance fixation and fastness, ensuring uniform and bright shades on finished textiles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Reactive Dyes Yellow 7

Price 70 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Purity : 99%

Solvent Color : Yellow

Physical Form : Powder

Solubility : Soluble in Water

Purple H3R Reactive Dyes

Price 50 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Purity : 99% min.

Solvent Color : Purple

Physical Form : Powder

Solubility : Soluble in water

Reactive Yellow 44

Price 80 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Purity : 98%

Solvent Color : Bright yellow

Physical Form : Powder

Solubility : Soluble in water

H Cold Series Reactive Dyes

Price 85 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Purity : >98%

Solvent Color : Consistent with shade

Physical Form : Powder

Solubility : Highly soluble in water

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry