Auramine Dyes

Auramine Dyes Specification

- EINECS No

- 219-573-5

- Ph Level

- 6-7 (1% solution)

- Other Names

- Basic Yellow 2, Auramine O

- Taste

- Odourless

- Resistance

- Good light and washing fastness

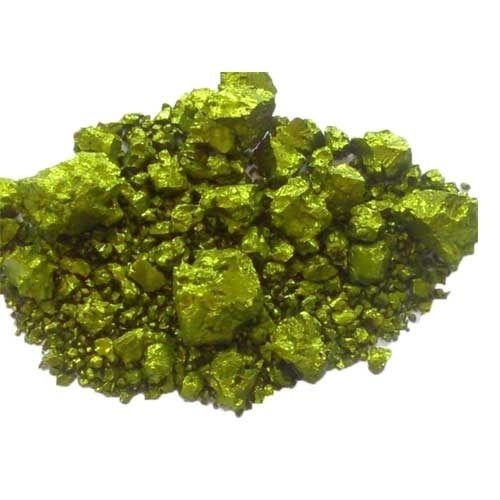

- Appearance

- Bright yellow powder

- Molecular Weight

- 303.83 g/mol

- Melting Point

- 267C

- Structural Formula

- C17H22N3Cl

- CAS No

- 2465-27-2

- Physical Form

- Solid

- Purity

- 99%

- Grade

- Industrial Grade

- Density

- 1.08 Gram per cubic centimeter(g/cm3)

- Molecular Formula

- C17H22ClN3

- HS Code

- 32041390

- Solubility

- Freely soluble in water and ethanol

- Poisonous

- Yes

- Shape

- Powder

Auramine Dyes Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 50000 Kilograms, , Per Week

- Delivery Time

- 3-7 Days

- Main Export Market(s)

- Asia, South America, Central America, Australia, Western Europe, Eastern Europe, North America, Middle East

About Auramine Dyes

Wide Range of Industrial Uses

Auramine Dyes are extensively used across multiple industries, including textiles, papermaking, leather, and biological staining applications. Thanks to their vivid yellow color and high degree of solubility, these dyes deliver consistent, reliable results on various substrates, making them highly valued by manufacturers and researchers alike.

Stability and Storage Information

Auramine Dyes offer a shelf life of up to 2 years when stored in a cool, dry, and well-ventilated area. Their stability under normal conditions, coupled with packaging in HDPE drums or bags, ensures both the integrity and safety of the product during extended storage and transport.

Safety and Handling Precautions

While Auramine Dyes are highly effective, they are also classified as hazardous and poisonous. It is essential to handle the powder with care, wearing appropriate protective equipment, and to avoid ingestion or inhalation. Ensure storage away from strong oxidizing agents to maintain safety and product quality.

FAQs of Auramine Dyes:

Q: How are Auramine Dyes typically applied in the textile and paper industries?

A: Auramine Dyes, due to their basic cationic nature, are primarily used for dyeing acrylic fibers, paper, and leather. The dye is dissolved in water or ethanol and applied through standard immersion or printing processes, resulting in vibrant, long-lasting yellow coloration with reliable resistance to light and washing.Q: What precautions should be taken when handling Auramine Dyes?

A: Auramine Dyes are poisonous and harmful if swallowed or inhaled. Always wear gloves, masks, and protective clothing during handling. Work in a well-ventilated area or use fume hoods, and store the product away from incompatible substances like strong oxidizing agents.Q: Where should Auramine Dyes be stored to maintain stability?

A: Store Auramine Dyes in cool, dry, and well-ventilated spaces, preferably in their original HDPE drum or bag packaging. Proper storage ensures up to two years of shelf life and stability under normal industrial conditions.Q: What is the recommended process for dissolving Auramine Dyes?

A: To dissolve Auramine Dyes, add the powder to water or ethanol at ambient temperature, stir until completely dissolved, and prepare the desired concentration for your application. The dye is freely soluble, making preparation quick and straightforward.Q: When should Auramine Dyes be avoided in industrial processes?

A: Avoid using Auramine Dyes in processes involving strong oxidizing agents, as incompatibility can cause hazardous reactions or degrade the dyes effectiveness. Always verify chemical compatibility before introducing them into any formulation or system.Q: What benefits do Auramine Dyes offer for industrial applications?

A: Auramine Dyes provide brilliant yellow coloration, excellent solubility, strong fastness properties, and stable performance in a range of industrial contexts. Their reliability and versatility make them a cost-effective choice for numerous manufacturing and laboratory staining needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fine Chemical Category

Blue Pigment Paste

Price 100 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Physical Form : Other, Paste

Molecular Weight : 576.08 g/mol

Appearance : Blue Paste

Structural Formula : C32H16CuN8

Copper Phthalocyanine Pigment

Price 60 INR

Minimum Order Quantity : 1 Kilograms

Physical Form : Solid

Molecular Weight : 576.08 g/mol

Appearance : Blue Powder

Structural Formula : C32H16CuN8 (Phthalocyanine Ring structure with copper at the core)

Guar Gum Powder

Price 65 INR

Minimum Order Quantity : 1 Kilograms

Physical Form : Solid

Molecular Weight : Not specified (Guar gum is a polysaccharide; approximate average 220,000 Da)

Appearance : Offwhite to pale yellow powder

Structural Formula : Polysaccharide composed primarily of galactomannan units

Basic Violet

Price 75 INR

Minimum Order Quantity : 1 Kilograms

Physical Form : Solid

Molecular Weight : 407.98 g/mol

Appearance : Purple Powder

Structural Formula : (C6H5C=N(C6H4N(CH3)2)2)Cl

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry