Bi Functional ME Series Dyes

Price 70 INR/ Kilograms

Bi Functional ME Series Dyes Specification

- Shelf Life

- 2 Years from date of manufacturing

- Shape

- Crystalline Powder

- Rubbing Resistance

- Good

- Strength

- 100% Standard

- Grade

- Industrial Grade

- Purity

- >98%

- HS Code

- 320416

- Solubility

- Soluble in Water

- Application

- Cellulosic Fibers (Cotton, Viscose, etc.)

- Structural Formula

- Varies per Dye

- Molecular Formula

- Varies per Dye

- Taste

- Odorless/Tasteless

- Density

- Gram per cubic centimeter(g/cm3)

- Size

- Custom Packaging

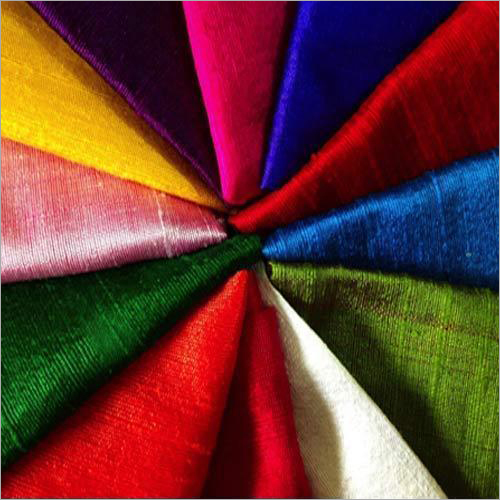

- Solvent Color

- As per shade

- Resistance

- Good Washing, Light & Rubbing Fastness

- Water Resistance

- Excellent

- Moisture (%)

- <1.5%

- Smell

- Odorless

- CAS No

- Various (depends on specific ME dye)

- Type

- Reactive Dye

- Usage

- Textile Dyeing and Printing

- EINECS No

- Not Available

- Physical Form

- Powder/Granular

Bi Functional ME Series Dyes Trade Information

- Minimum Order Quantity

- 500 Kilograms, ,

- Supply Ability

- 50000 Kilograms, , Per Week

- Delivery Time

- 3-7 Days

About Bi Functional ME Series Dyes

Bi Functional ME Series Dyes:-

Our company is reckoned among the leading manufacturer and exporter of excellent quality Bi Functional ME Series Dyes. The reactive dyes are produced by linking Vinyl Sulphone group to chromophore through a bridge link of monochloro triazine group. Bi Functional ME Series Dyes are pure in composition, having high fixation efficiency and pose no risk of staining the adjacent white patches. Such type of dye is used on cellulosic materials at low dyeing temperature of 60ºC.

A summary of the notable features of Bi Functional ME Series Dyes are as given below:

- Stable to acid hydrolysis

- Unfixed dyes can be washed off easily

- Little risk of staining of adjacent whites

- Excellent leveling properties

- High fixation efficiency

- Good fastness properties.

MOQ: 50kg

| SHADES | SHADES | PRODUCTS | C. I. NAME | CAS NO. |

|---|---|---|---|---|

| Yellow ME4GL | Yellow 160A | 129898-77-7 | ||

| G.Yellow MERL | Yellow 145 | 93050-80-7 | ||

| Orange ME2RL | Orange 122 | 79809-27-1 | ||

| Red ME3BL | Red 194 | |||

| Red ME4BL | Red 195 | 93050-79-4 | ||

| Red ME6BL | Red 196/250 | |||

| Red MERBL | Red 198 | 145017-98-7 | ||

| Red ME3BN | Red 180 | 72828-03-6 | ||

| Red ME3GL | Red 223 | |||

| N. Blue ME2GL | Blue 194 | 93050-78-3 | ||

| N.Blue BRF | Blue 221 | |||

| Blue BF | Blue 222 | |||

| Blue ME2RL | Blue 248 | |||

| Black MEGR | ||||

| Black HFGR |

High Dye Content for Superior Results

ME Series Dyes boast high dye content, ensuring deep, vivid shades and efficient coverage with minimal usage. Their strong concentration translates to cost effectiveness and vibrant results across all textile applications.

Optimized Fixation and Application

These dyes are engineered to fix optimally at 60C, streamlining processing and ensuring reliable, uniform color. Their affinity for cellulosic substrates such as cotton and viscose makes them suitable for a wide range of fabric treatments.

Outstanding Fastness & Resistance

ME Series Dyes provide excellent washing, light, and rubbing fastness, ensuring longevity of color and fabric integrity through repeated use and exposure. The water resistance further secures their utility in various textile environments.

Flexible Discharge Printing Capabilities

Designed with dischargeability in mind, these dyes facilitate both white and colored discharge printing, enabling intricate and detailed design work on cellulosic fibers through advanced printing techniques.

FAQs of Bi Functional ME Series Dyes:

Q: How should Bi Functional ME Series Dyes be used for optimal results in textile dyeing?

A: For best results, the dyes should be applied to cellulosic fibers such as cotton or viscose, with fixation performed at 60C. Medium salt levels help promote fixation and color yield; follow recommended dosing for deep, even coloration.Q: What is the primary benefit of utilizing ME Series Dyes in industrial textile printing?

A: ME Series Dyes deliver excellent affinity for cellulosic substrates and high fastness properties, resulting in vibrant prints that resist fading, washing, and rubbing. Their dischargeability also allows for versatile print effects, including intricate colored and white patterns.Q: When is discharge printing recommended with ME Series Dyes?

A: Discharge printing is recommended when white or colored patterns are desired on cellulosic textiles. The dyes good dischargeability supports clear, defined designs, producing sharp results in both styles of discharge prints.Q: Where can these dyes be applied and which substrates are suitable?

A: ME Series Dyes are ideal for use on cellulosic fibers, primarily cotton and viscose, making them suitable for apparel, home textiles, and fashion printing sectors. Their application is widespread in commercial dyeing and printing units.Q: What process steps are involved in the application of ME Series Dyes for cellulosic fibers?

A: The process involves preparing the dye bath, adding medium salt levels, applying the dye to the fabric, fixing at the recommended 60C, and then rinsing. Post-process, additional washing ensures removal of excess dye and maintains fastness.Q: What is the typical shelf life and storage recommendation for ME Series Dyes?

A: ME Series Dyes have a shelf life of two years from the date of manufacturing. They should be stored in a cool, dry place in closed containers to maintain strength, solubility, and purity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Industrial Reactive Dyes

Price 55 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Usage : Other, Textile Industry, Leather Industry, Paper Industry, Dyeing, Printing

Solubility : Easily soluble in water

Application : Other, For Dyeing and Printing Cellulosic Fibers

Type : Other, Industrial Reactive Dye

Reactive Hot Dyes

Price 90 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Usage : Other, Textile Industry

Solubility : Soluble in Water

Application : Other, Dyeing of Cotton and Cellulose Fibers

Type : Reactive Dye

Vinyl Sulphone Reactive Dyes

Minimum Order Quantity : 500 Kilograms

Usage : Textile Dyestuffs

Solubility : In water

Application : Industrial

Type : Reactive Dye

|

MEGHA INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry